The success of the crop starts from the land operation which is related to machinery, planting, and harvesting process.

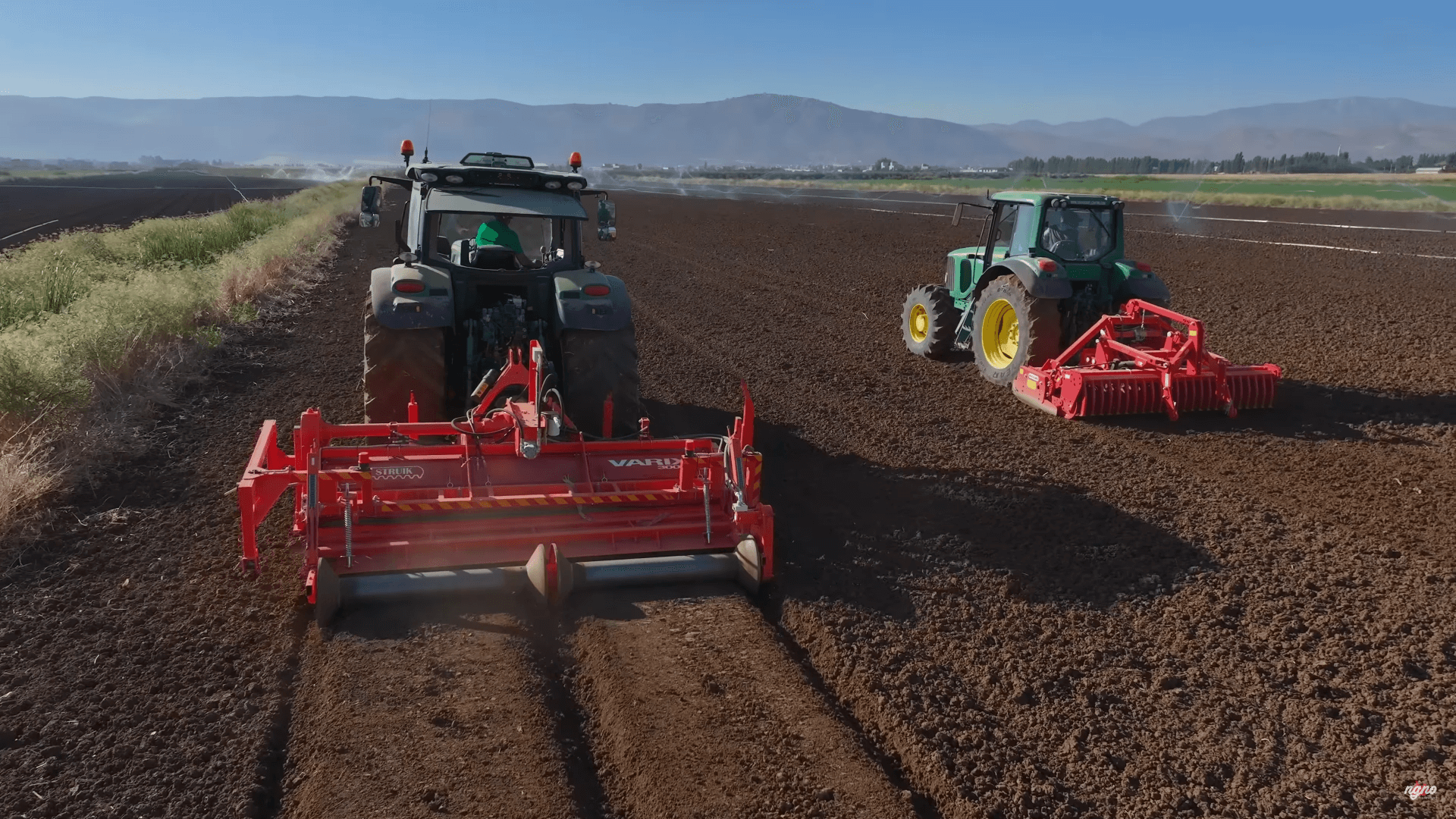

Advanced machinery and technologies are used in the planting phase to cover wide areas (around 800 Hectare) in a short period.

Before start planting the seeds in the soil, there are many steps for the land tillage:

Soil Analysis

Cultivation

Seeding

Fertilization

Irrigation

Harvest

Each land has particular characteristics and using the suitable fertilizer during the soil shopper phase happens after a series of tests achieved in specialized labs.

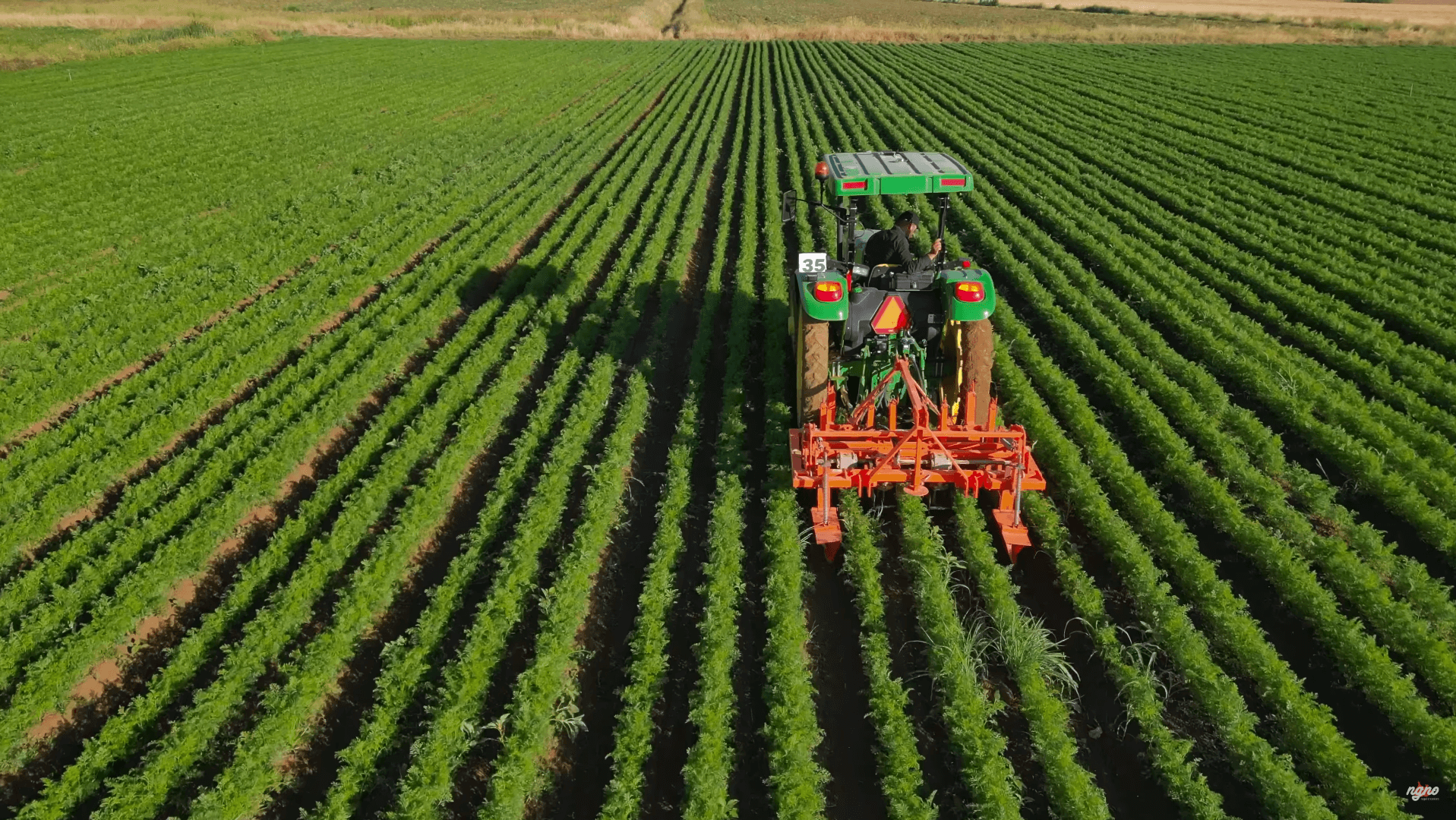

About carrots, there is a specific machine for the planting process it provides an accurate distribution of carrot seeds in the soil.

Fresh products uses an advanced irrigation technology and method that leads to reduce the water consumption with high efficacy on the product growth and it is called sprinkler irrigation system.

The balance between irrigation and fertigation in the planting process affects every level of quality and the consumer experience of the final product.

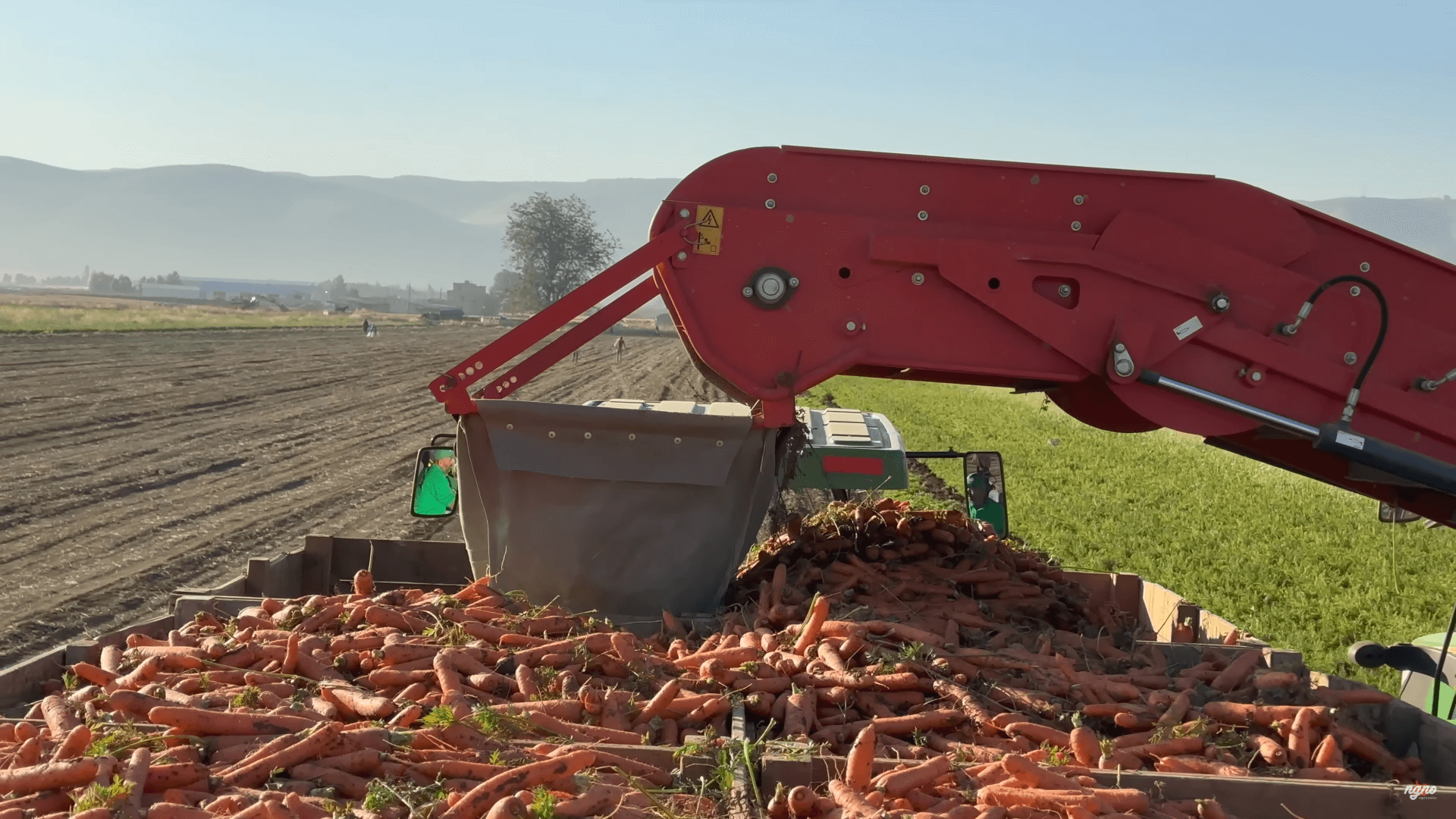

Harvesting occurs when carrots reach an adequate size. Most varieties are ready to be picked in 95-135 days, the sweetness and the storage potential of crops increase with maturity. The engineers’ experience is required to decide whether the crop is ready for harvesting or not.

The soil temperature condition is vital for the harvesting timing. Cooling the soil leads to reducing the field heat as it is a primary step before the storage stage. A slightly low temperature of the soil is crucial for the harvesting process.

It is very important to avoid scratching carrots during the harvesting process to reduce the possibility of being attacked by sclerotinia during storage. There are two used ways to harvest carrots, either by using a top lifter carrots harvester machine or by using a tractor-drawn mounted digger.

Choose the perfect seeds for each crop.

Periodic audit and daily checkup.

Perform soil laboratory tests.

Perform water laboratory tests.

Products receiving.

Raw Material inspection.

Analysis and reports.

Compliance with food safety standards.

Registering the finished products on the ERP system.

Storing the finished products in a cold warehouse.

Shipping to the markets.

Quality report.

Hydrocooling.

Packaging.

Labeling.